Soldering irons are essential tools in the world of electronics. As a conductive metal material with a relatively low melting temperature and relatively quick solidifying time, Solder is perfect for adding components into circuits. The first electrical soldering irons were created at the turn of the 20th Century, as documented in issue 92 of Scientific American released in 1905.

These days, soldering irons come in many different forms, each with unique applications. All these types of irons are available from various online electronic parts suppliers. Here’s a look at the different types you can expect to see and what makes each one different from the other.

Hot Knife

Hot knife soldering irons are used for cutting as well as soldering. A double-edged blade is attached to a heating element – meaning that the blades become extremely hot. This allows for the cutting and sealing of metals and fabrics. Hobbyists occasionally modify their simple irons to act as rudimentary hot knives.

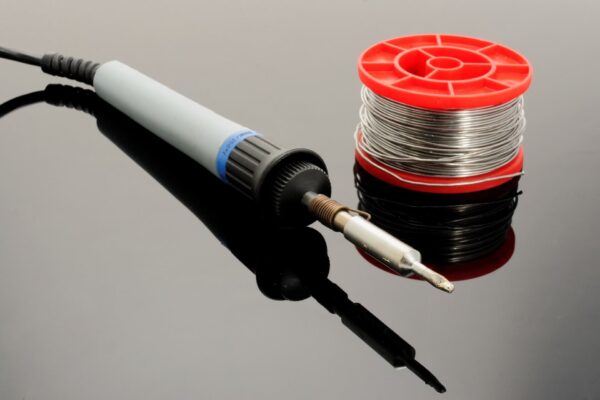

Simple Iron

As the name might suggest, simple irons are the most basic soldering irons. They are powered by mains electricity and usually use between 15 and 35 watts of power. They are not temperature controlled, and their heat is determined by thermal equilibrium. When they are heating a larger object, their temperature will drop. A simple soldering iron is perfectly good for attaching wires and conventional components into a circuit. They are cheap and plentiful.

Cordless Iron

Cordless irons are highly portable and favored by electricians on call-outs. They can be powered by battery but are more often heated using canisters of butane gas that fit neatly into the handling surface. Gas-powered cordless soldering irons can be temperature regulated by increasing gas flow to the tip in a similar way to how a gas-powered stove might be turned up. Cordless irons are extremely useful – but potential hobbyist purchasers should be wary of the costs that come along with gas-powered devices of all sorts.

Temperature Controlled Iron

Professional electronics workers and hobbyists with large projects usually opt to use a temperature-controlled soldering iron. Because thermal equilibrium determines that heat will be lost from a simple iron depending upon the size of the item it is heating, several mechanisms have been invented to keep soldering irons at a stable temperature no matter what it is heating. The most popular kind of temperature control mechanism for professionals involves the use of a thermostat that senses the heat of the iron’s element and adjusts the power supply in order to keep it regulated. Hobbyists tend to use manually regulated soldering irons that allow specific temperature changes to be ‘dialed in’ using a switch resembling a light dimmer.

Soldering Tweezers

Soldering tweezers are used for extremely delicate work attaching and detaching micro components from Printed Circuit Boards. Two heated tips allow a worker or hobbyist to maintain solder liquidity whilst working to move a component. Soldering tweezers are not essential bits of kit for hobbyists but can be useful if you have an extremely complex miniature job to do.